Introduction

|

Drag chain conveyors handle a wide range bulk materials ranging from Ash to Zinc. The versatile design and efficient utilization of space means the conveyor has a smaller footprint compared to other conveying technologies and a smaller, more energy efficient drive. Our Drag Conveyor moves material distances ranging from 20 to 200 feet or more. A Hapman Drag Conveyor is equipped with the industry’s most durable chain; an exclusive drop-forged, case hardened formula that contains a hard exterior coupled with a softer, malleable core. This combination provides the highest level of abrasion resistance while mitigating the risk of stress and breakage. |

|

Drag Chain Conveyor In Action

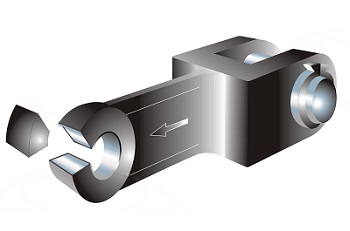

Industry's Most Durable Chain

- Core hardness for strength and ductility is set at 300-400 BHN.

- Machined yokes provide a tight controlled fit between links. Each link is individually pinned for ease of replacement.

- Chain link bores are machined to provide a full pin/bore bearing area for maximum strength.

- Chain links are totally carburized to provide an effective case hardness of 550-650 BHN (60Rc) at a depth of 0.03" to 0.04".

|

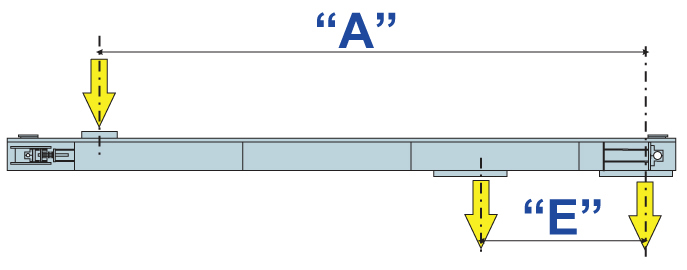

Standard Horizontal Conveyor |

Features/Options

The Hapman Drag Conveyor is engineered with the necessary features required for each application. Conveyor size, flight selection, single or dual chain layout, housing, diverting discharge ports, high-temperature components, and other key features will be evaluated by our design team to effectively move all of your material.

Layout and Design

Conveying with an En-Masse drag conveyor affords you the ability to move large volumes of material in virtually any direction or layout. The flexibility in engineered design means we can provide the optimum conveyor layout to achieve all of your material handling and operating goals.

Horizontal

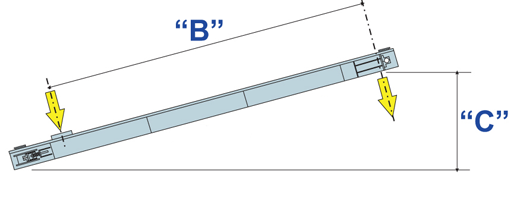

Inclined

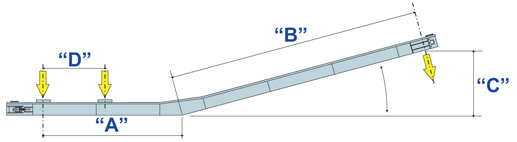

L-path

En-Masse Conveyor with Spring-Loaded Screw Take Up Terminals and Support Legs

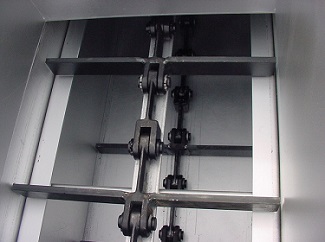

The above image shows the tail end of a twin En-Masse conveyor. This type of conveyor is recommended when chain pull is too great for a single chain or the capacity requirements exceed a single chain. The twin conveyor requires less space than running multiple separate conveyors. The off-set, dual shaft is our engineered design for providing the longest, most reliable operation in the industry. The off-setting shafts allow for individual chain movement and take-up, maintaining optimum flow and capacity.

En-Masse Drag Conveyor

The En-Masse drag operating principle affords significant advantage over other conveying methods:

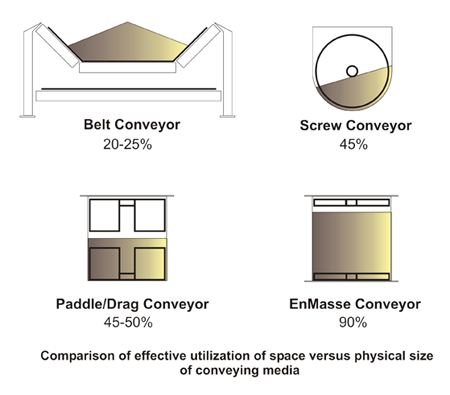

Size to capacity ratio - A typical belt conveyor uses 20-25% of available conveying space to effectively move material. A typical drag or paddle conveyor uses 45-50% of conveying space, while the En-Masse drag conveyor uses 90% of the available conveying space to effectively move material. This means the overall size of the En-Masse drag conveyor is greatly reduced when compared to other conveying technologies moving the same volume.

Size to capacity ratio - A typical belt conveyor uses 20-25% of available conveying space to effectively move material. A typical drag or paddle conveyor uses 45-50% of conveying space, while the En-Masse drag conveyor uses 90% of the available conveying space to effectively move material. This means the overall size of the En-Masse drag conveyor is greatly reduced when compared to other conveying technologies moving the same volume.- Ability to handle product in many conveyor configurations – Horizontal, Inclined, Vertical, L-path, Z-path, and looping.

- Ability to convey over long distances – En-Masse drag conveyors can effectively convey material across terrain and cover an average of 200 feet (61 meters) or more.

- Engineered for a wide range of bulk material – From Ash to Zinc the En-Masse drag conveyor design allows for large volumes of material to be moved effectively

It's All in the Chain and Flight Design

The internal chain is the work horse of our En-Masse drag conveyor. Understanding the design characteristics will help you to understand why our chain is engineered for durability, reliability and longevity.

- Impact and Wear Resistance – Our chain is case hardened with a strong ductile core. This engineered balance between hardness and malleable provides the right wear resistance without becoming brittle.

- Fatigue – A chain designed to proportion the steel where needed coupled with dropped-forged steel alloy links constructed to avoid premature wear

- Bearing Surfaces & Finish – Precision machined with tight tolerance, our bearing and surface finish process significantly limits joint articulation wear

- Manufacturing Techniques – We maintain strict dimensional tolerances and documented quality control procedures. We select the proper alloys for the application and have a proven system in place to verify production according to standards.

- Flight Attachment Method – Welded and bolted

- Chain Weight and Pitch – We specifically develop and design for En-Masse drag conveying operations providing the appropriate strength to weight ratio for optimum durability and longevity

Our drop-forged conveyor chains and flight assemblies are specifically engineered for En-Masse drag conveying applications and provide superior longevity over other designs.

Flight Options

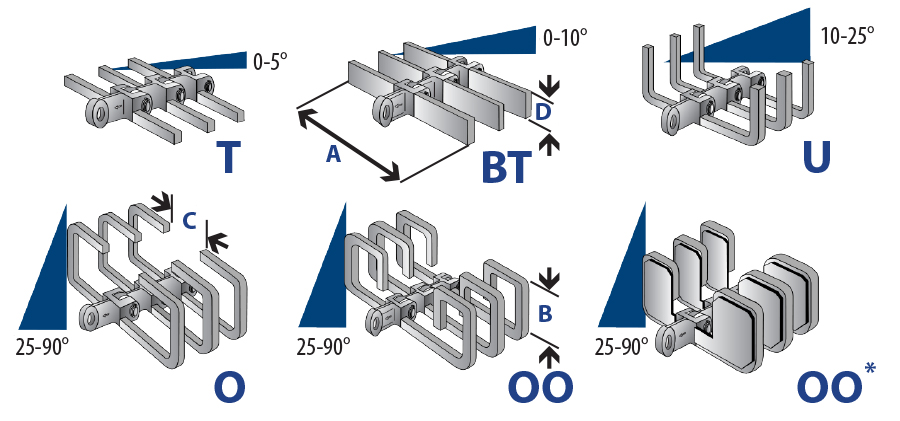

These flight options represent the most common designs. Other styles are available. The T- and BT-style flights are used for horizontal through slight incline applications, normally between 0° and 12°. The U-style can be used for horizontal/incline combinations through approximately 25°. The modified BT, O, OO, and OO with filler plates are utilized in horizontal/inclined applications through 90°.

Drag Chain Conveyor Application - Aluminum Foundry Transfer Process

Single Strand Top Carry Drag Chain Conveyor was engineered to automate the foundry transfer process. The conveyor features a design that offers minimal maintenance requirements, and abrasion resistant construction. Automating the foundry sand transfer process significantly reduced ergonomic risk factors and improved the daily physical strain on mold makers, resulting in lower disability insurance costs and reduced claims as well as 20% increased production capacity.

Single Strand Top Carry Drag Chain Conveyor was engineered to automate the foundry transfer process. The conveyor features a design that offers minimal maintenance requirements, and abrasion resistant construction. Automating the foundry sand transfer process significantly reduced ergonomic risk factors and improved the daily physical strain on mold makers, resulting in lower disability insurance costs and reduced claims as well as 20% increased production capacity.

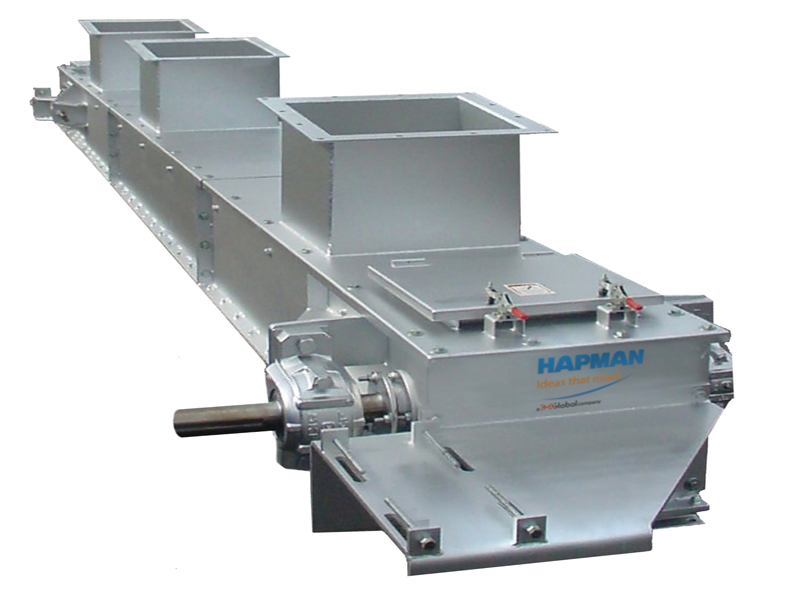

En-Masse Conveyor Application - Salt Cake

En-Masse conveyor handling Salt Cake at a rate of 10,000 lbs/hr to a liquor tank at a 10-degree incline. Installation temperature is +/- 400 degrees Farenheit operating 24/7. Construction of the conveyor is 3/8" abrasion resistant (A.R.) sidewalls and 1/2" A.R. bottom plates. The drive station is fabricated of stainless steel to prevent corrosion due to caustic steam produced by the liquor tank.

This is our 19" 142STD BT2 single-strand, drop-forged chain with 1/2" x 2" BT flights every other pitch. A chain speed of 15 FPM produces excellent chain wear and longevity, even in corrosive environments.

This is our 19" 142STD BT2 single-strand, drop-forged chain with 1/2" x 2" BT flights every other pitch. A chain speed of 15 FPM produces excellent chain wear and longevity, even in corrosive environments.

The inspection door is comprised of high temperature silicone gasketing and a removable expanded metal safety screen.

The inspection door is comprised of high temperature silicone gasketing and a removable expanded metal safety screen.

En-Masse Conveyor Application - Potash

En-Masse conveyor handling Potash at a capacity of 800TPH. This system has an operating product temperature of 200 degrees Celsius.

The complete conveyor system is located in the Potash processing facility.

The complete conveyor system is located in the Potash processing facility.

Technical Data Sheet

Technical Data Sheet